My Project

The goal of my project is to understand how motor works and see if I could find some ways to make motor’s appearance not so motor.

Because motor is used everywhere and I want to first admire its beautiness in its circuit and fabrication and then see if I could make a motor not for industry use, but just for aesthetics and kinectic movements.

My plan

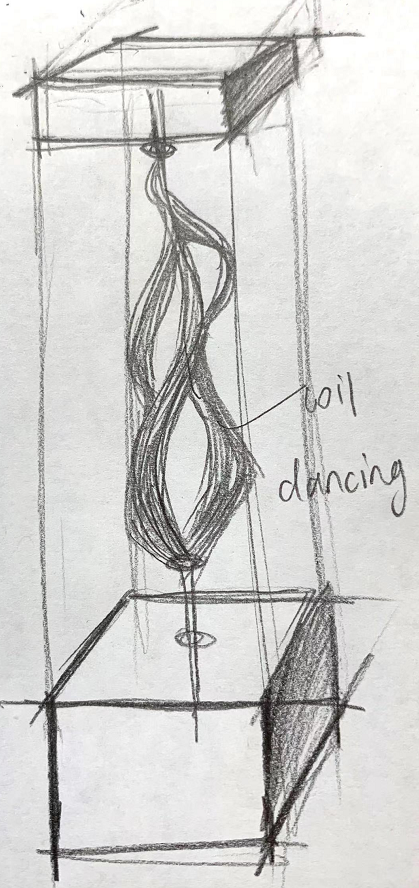

coil is a dancing figure

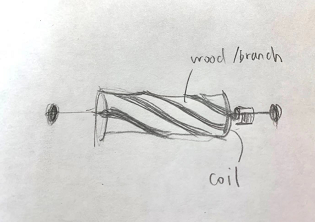

armature is wood/fabric/branch, some traditional fabrication material

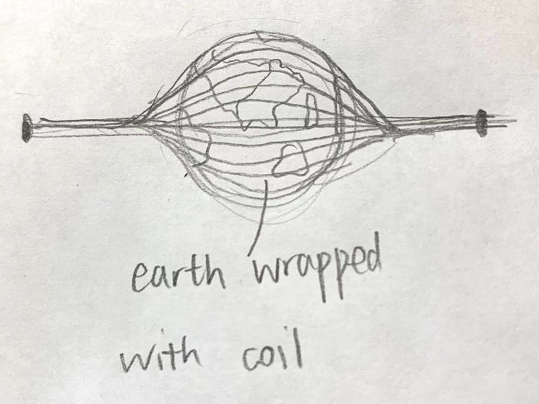

coil winding around an earth model makes it looks like latitude on earth

My experiment

simple motor

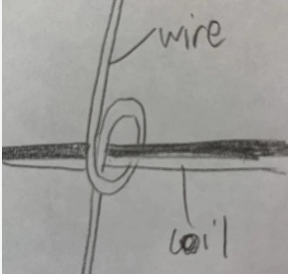

After I keep the contact part of my coil and wire to be half conductive and half insulated as Jeff suggests, it can turn all around.

#### DC I want to do a simple experiment of how to turn a wood motor. It took me a lot of effort to make the fabrication because I think it would be romantic to make a well fabricated wood to rotate itself. I cut the 2 rod.

draw the sketch and cut it with hand saw.

My favorite Mortise and tenon joint structure.

looks nice right?

Would not work! I wind the coil, I put it and mount them roughly to see if it works but it wouldn't! The wood is too heavy and the motor cannot support the force to compensate the friction caused by its weight. Also, the conductive tape is eaily to be worn out by friction. I learned a lot of lesson from that.

I try to save it with my last trial, using a bearing to reduce the friction of rotation. Still it cannot work.

And then I finish the fabrication to make this motor die gracefully.

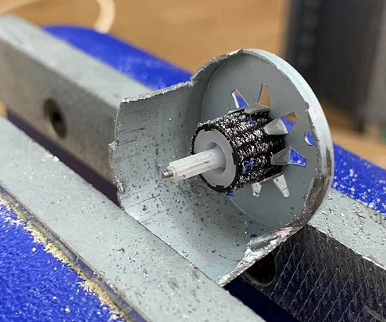

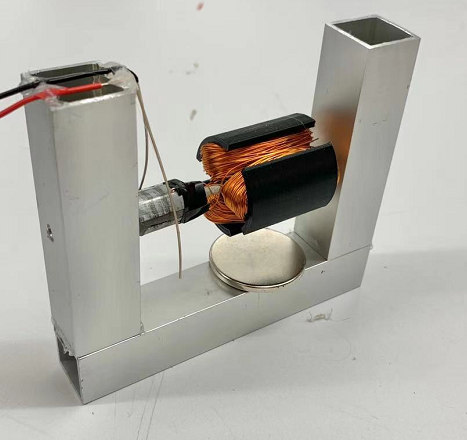

#### Switch the aim I thought it would be too hard for me to make motor be both creative and functional. So I decide to be a not creative guy just learning how to make my own motor. I 3D model and print the basic structure for holding the coil. this part is easy.

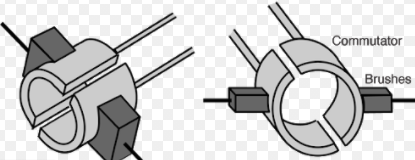

However, I think the most difficult part for building a motor is it commutator. It took me a lot of effort to make it.

I do not have any metal sheet material So I cut the metal from a stepper motor. I think this must be the most stupiest way for building a commutator. I also use the J-B weld to shape the part for holding these 3 metal pieces.

It does not work at first.

"I should be more hard working at winding coils." So I reprint the armature and wind coil for an hour. Then it works. Motor is not only energy consuming, but also time consuming.

I also build a stepper motor for fun following the tutorial I see in youtube.

Conclusion

I am still passionate about my original ideas and now I have master some skills about making motors. Hope I could achieve my original goal some day.