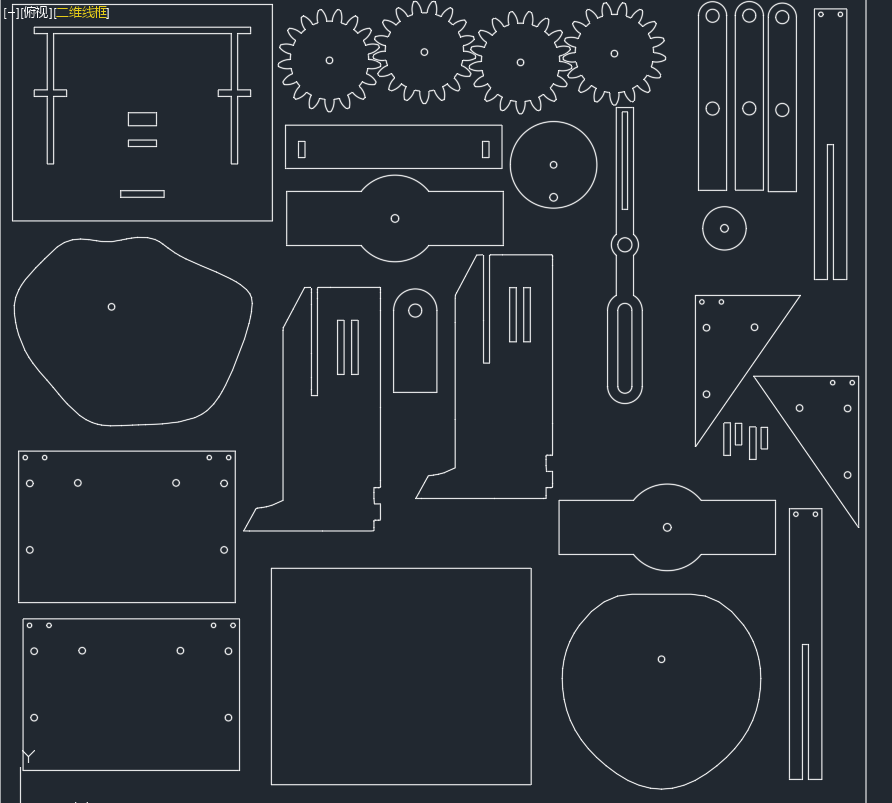

It is always not the same case when considering how to make it happen in real world. I figure out I need to consider more.

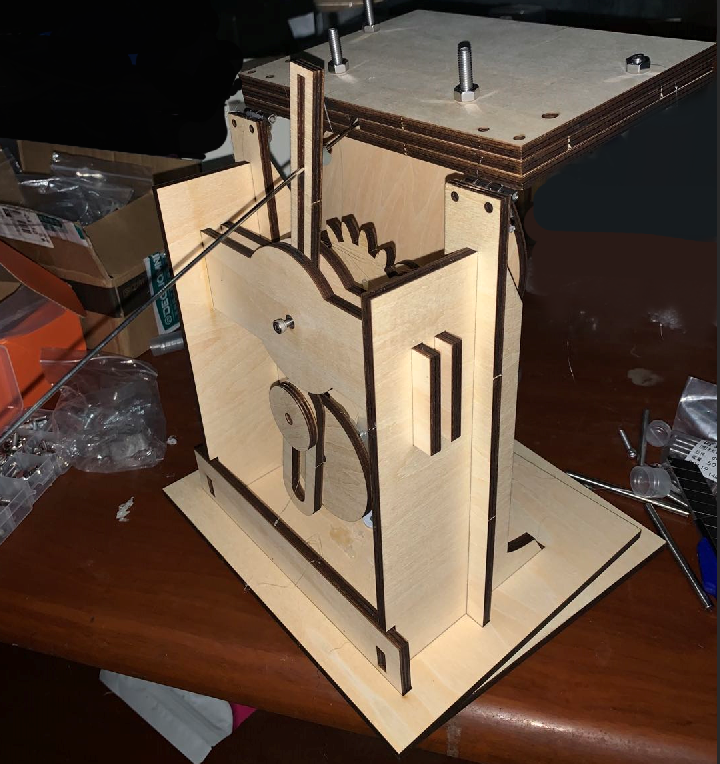

I did one version of prototype first and then I figure out a lot of problems.

Problem one: shaft connection

Right now the shaft is connected with the lasercut wood just by glue gun and there is no way I can keep the shaft always in place. Sometimes it would just come out of the hole.

So I figure out that I need these 2 components:

Since I am using a shaft whose diameter is 6mm. I bought its flange. Inner Diameter is also 6mm.

Also, I need to keep the shaft from slipping through the hole. However, I also need to keep the shaft rotating without too much friction. It seems that I need to add friction between the shaft and its connection hole. Meanwhile, I also need to reduce the friction. So I figure out that I need to add some bearing. The outside diameter of the bearing is 12 mm. The hole of the wood for the bearing is 11.8mm in diameter, so the bearing would be friction tight with the wood. The inner diameter of the bearing is 6 mm. It would also friciton tight with the shaft.

Problem two: too big

I want the whole mechanism to be smaller. Because I have gone through a heart breaking process already by throwing away all my things in my previous mountain project when I was flying back to China. I never want to experience that anymore. So I decide that my thesis would be a relative smaller size so that I could carry it anywhere.